Inboard Engine Drive Systems

Inboard engines are a popular choice for larger powerboats. These engines are installed inside the hull of the boat, typically located near the center or stern, and are connected to a propeller shaft that extends through the hull to the propeller. Inboard engines are known for their power, durability, and efficiency, making them well-suited for a variety of boating activities, from cruising and fishing to watersports.

A Typical Inboard Engine

Advantages of Inboard Engine Drive Systems

Power and Performance

- High Torque: Inboard engines generally provide more torque than outboard engines, which is particularly beneficial for larger boats that require more power to move through the water.

- Smooth Operation: The centralized location of the engine provides better weight distribution, contributing to a smoother and more stable ride, especially in rough seas.

Durability

- Built for Longevity: Inboard engines are designed to be robust and durable, often lasting many years with proper maintenance. Their internal location protects them from the elements, reducing exposure to saltwater and sun, which can extend the engine’s lifespan.

Low Center of Gravity

- Stability: The inboard engine’s placement low in the boat helps lower the center of gravity, enhancing the boat’s stability and handling, particularly in larger vessels.

Open Transom

- Clear Deck Space: With the engine located inside the hull, the transom is often left clear, providing more usable deck space for activities like fishing or diving.

Less Noise and Vibration

- Quieter Operation: Because inboard engines are located within the hull, they are generally quieter than outboard engines, and their noise is further reduced by insulation and the boat’s structure.

Disadvantages of Inboard Engine Drive Systems

Maintenance Complexity

- Difficult Access: Inboard engines can be more challenging to access for maintenance and repairs since they are housed inside the boat’s engine compartment. This can make routine maintenance tasks, such as oil changes or engine inspections, more labor-intensive.

- Higher Costs: Due to the complexity of the installation and the engine itself, maintenance and repair costs for inboard engines can be higher compared to outboard engines.

Initial Cost

- Higher Purchase Price: Inboard engines tend to be more expensive upfront compared to outboard engines, reflecting their higher power output and more complex installation.

Draft Considerations

- Deeper Draft: Inboard engines typically result in a deeper draft, which can limit the boat’s ability to navigate shallow waters.

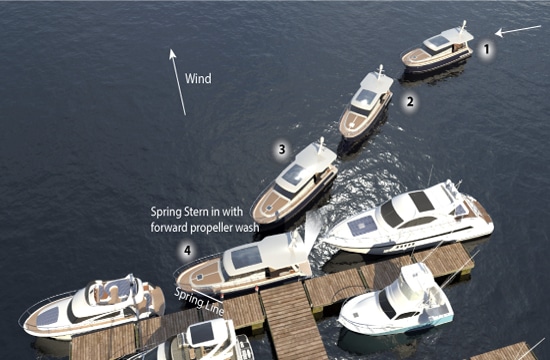

Reduced Maneuverability at Low Speeds

- Handling: Inboard-powered boats can be harder to maneuver at low speeds, especially in tight spaces like marinas, due to the fixed position of the propeller. Reversing can be a real problem.

Typical Fuel Types for Inboard Engines

Inboard engines typically run on one of two fuel types

- Gasoline

Advantages: Gasoline engines are lighter and generally less expensive than diesel engines. They are easier to start and are more common in the recreational boating market, particularly for smaller inboard engines.

Disadvantages: Gasoline engines are less fuel-efficient and have a shorter lifespan compared to diesel engines. They are also more prone to fire hazards due to the volatility of gasoline.

- Diesel

Advantages: Diesel engines are more fuel-efficient, offering better range and lower operating costs over time. They are also more durable and can handle the heavy loads typically required by larger vessels. Diesel fuel is less flammable than gasoline, reducing fire risk.

Disadvantages: Diesel engines are heavier and more expensive initially. They can also be louder and produce more vibration than gasoline engines.

Popular Fuel Choice

For larger powerboats, diesel is the more popular fuel choice due to its superior fuel efficiency, longevity, and safety advantages. Diesel engines are particularly favored for offshore cruising, commercial vessels, and larger yachts. However, the engines themselves are more expensive but ongoing fuel cost tends to be less due to efficiency.

Types of Inboard Engine Drives

Direct Shaft Drive

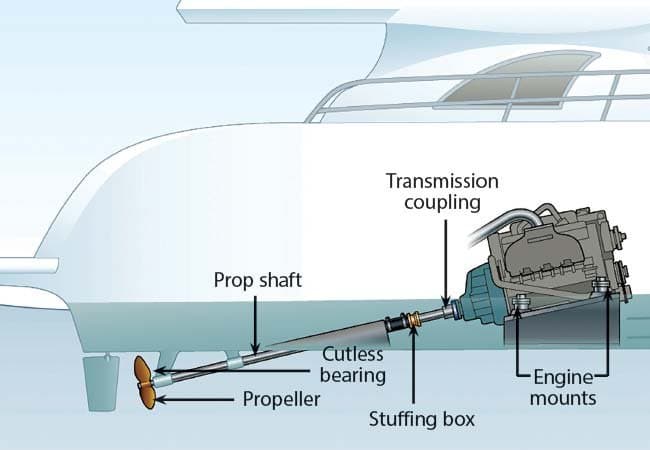

In a direct shaft drive system, the engine is mounted near the center of the boat, and the drive shaft extends directly from the engine to the propeller at the stern. The shaft passes through a stuffing box to prevent water from entering the hull.

Advantages:

- Simplicity: Direct shaft drives are straightforward, with fewer moving parts, leading to greater reliability and easier maintenance.

- Durability: This system is highly durable and well-suited for long-distance cruising.

- Efficiency: It is efficient at transferring engine power directly to the propeller with minimal power loss.

Disadvantages:

- Fixed Propeller Position: The propeller’s fixed position can make low-speed maneuvering more challenging, particularly in tight spaces.

- Draft: The propeller shaft often results in a deeper draft, which can limit access to shallow waters.

- Vibration: Shaft drives can introduce more vibration into the hull, potentially affecting comfort.

V-Drive

A V-drive system is a variation of the direct shaft drive, where the engine is mounted towards the stern, and the drive shaft is directed forward from the engine before turning back towards the propeller in a V-shape. This allows for better use of interior space.

Advantages:

- Space Efficiency: V-drives free up more space in the cockpit and cabin by allowing the engine to be placed further aft.

- Improved Balance: Placing the engine closer to the stern improves weight distribution, enhancing performance and stability.

- Better Access: V-drives can offer better access to the engine for maintenance compared to traditional direct drives.

Disadvantages:

- Complexity: The V-drive system is more complex and has more moving parts than a direct shaft drive, potentially leading to higher maintenance costs.

- Cost: V-drive systems are typically more expensive due to their complexity and installation requirements.

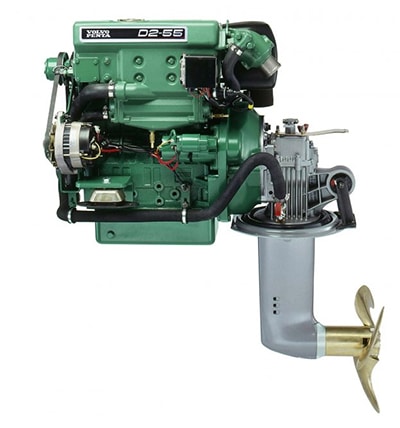

Saildrive

While primarily used in sailboats, saildrives are occasionally found in powerboats, particularly in catamarans. The engine is mounted inside the boat, connected to a leg that extends downward, similar to an outboard motor.

Advantages:

- Compact Design: Saildrives offer a compact installation, saving space inside the boat.

- Reduced Vibration: Saildrives reduce vibration and noise compared to direct shaft drives, offering a quieter and smoother operation.

- Easy Maintenance: The saildrive’s design allows for easier access to the propeller and lower unit for maintenance.

Disadvantages:

- Limited Use in Powerboats: Saildrives are not commonly used in powerboats and are better suited for sailboats, where the advantages of compactness and reduced drag are more critical.

- Sealing Issues: The through-hull design of saildrives can be prone to sealing issues, which could lead to potential leaks if not properly maintained.

- Lower Power Capacity: Saildrives typically handle lower power outputs, making them less suitable for larger powerboats that require more powerful propulsion systems.

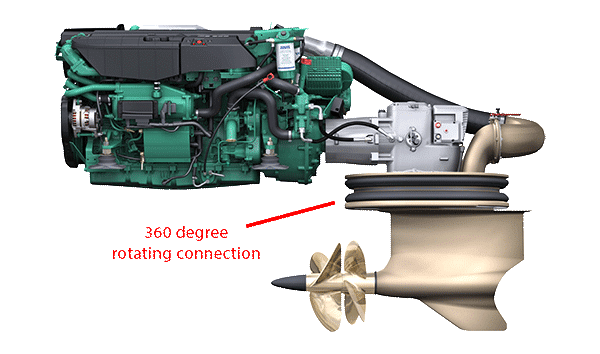

Azimuth or Pod Drives

An azimuth drive utilizes an inboard engine connected to a complex gearbox leading a vertical shaft through the hull with another gear arrangement to a horizontal shaft attached to the propeller. In this sense, it is much like a saildrive except that the entire arrangement allows for the lower unit called a pod to rotate 360 degrees. This allows for thrust in any direction without the need for a traditional rudder.

Advantages:

- Enhanced Maneuverability: Provides 360-degree directional thrust, significantly improving the vessel’s ability to maneuver in tight spaces and during docking.

- Greater Efficiency: Optimizes propulsion and fuel efficiency by allowing more precise control over thrust direction and reducing drag.

- Simplified Control: Allows for joystick control, which simplifies the handling of the vessel, especially in complex maneuvers or adverse conditions.

Disadvantages:

- Higher Cost: Generally more expensive to install and maintain compared to traditional propulsion systems.

- Complexity: The advanced technology and mechanics involved can lead to more frequent maintenance and repair needs.

- Sealing Issues: The large through-hull design of azimuth designs can be prone to sealing issues, which could lead to potential leaks if not properly maintained.

- Potential for Damage: The rotating pod is more exposed and susceptible to damage from debris or groundings compared to traditional propeller and rudder setups.

Conclusion

Inboard engines offer a robust and durable option for larger powerboats. They provide the power and torque necessary for moving large vessels efficiently through the water while offering benefits like stability, low noise levels, and a clear transom for increased deck space. Diesel fuel is the preferred choice for larger boats due to its efficiency, durability, and safety, although gasoline is still used in some recreational applications.

When choosing an inboard engine system, the type of drive—whether direct shaft, V-drive, or saildrive (though more common in sailboats)—should be considered based on the boat’s intended use, layout, and the desired balance between performance, space efficiency, and maintenance complexity. Each system has its own set of advantages and disadvantages, and understanding these will help boat owners make informed decisions that best suit their boating needs.