Propellers

Except in jet-propelled boats, propellers are a critical component for powerboats, as they directly affect the boat’s performance, efficiency, and handling. Understanding propeller characteristics, such as pitch, materials, and design, helps in selecting the best propeller for different boating activities and engine types.

Propeller Pitch and Its Impact

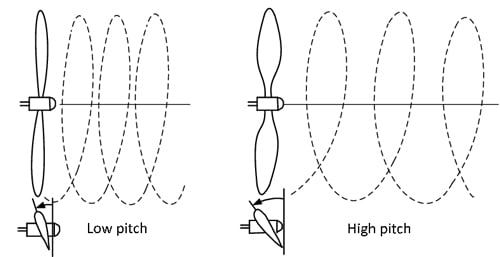

Pitch refers to the distance a propeller would theoretically move in one complete rotation if it were moving through a soft solid, such as jello. In simpler terms, pitch is the angle of the blades on the propeller and determines how far the boat moves forward with each rotation of the propeller.

Pitch directly affects the boats acceleration and top speed. A large pitch will slow the acceleration of the boat but push the boat to a higher speed. Conversely, a fine pitch will increase acceleration but reduce the top speed of the boat

Low Pitch: A lower pitch propeller means the blades are angled less steeply. This allows the engine to reach higher RPMs more quickly, providing better acceleration. However, it results in lower top speed and can lead to increased fuel consumption due to higher engine revs. A low pitch is equivalent to operating in a low gear in a car – the engine can easily get the car moving but must rev very high to get more speed.

High Pitch: A higher pitch propeller has more steeply angled blades, which pushes more water and can result in higher speeds at lower RPMs. This improves fuel efficiency at cruising speeds but reduces acceleration. High-pitch propellers can also be more prone to cavitation if the boat is not able to reach sufficient speeds or if the engine is underpowered. A high pitch is equivalent to operating in a high gear in a car – the engine struggles to get moving from a standstill.

|

Historical Insight: When the Wright brothers were designing the propellers for their early aircraft, they initially believed that the shipping industry would have developed sophisticated engineering equations for propeller design that they could use. However, upon consulting with marine engineers, they discovered that no such formulas existed. Instead, ship propellers were typically designed through empirical methods, based on trial and error and what had historically proven to work best, rather than on precise mathematical calculations. This realization led the Wright brothers to develop their own aerodynamic theories and equations to design an effective propeller for their aircraft. |

Modern Propeller Designs

Recent advances in propeller design have focused on improving fuel efficiency, reducing noise and vibration, and enhancing performance. Key modern designs include:

Cupped Propellers: These propellers have a slight curve or “cup” on the trailing edge of the blade, which helps improve grip in the water, reducing slip and cavitation, and increasing efficiency. The curve helps the water slide off the blade and thus backfills the area behind the blade reducing the sudden pressure drop.

High-Efficiency Blades: Designs with fewer blades or with optimized blade shapes can reduce drag and increase speed. These are often used in racing or high-performance applications.

Ventilated and Vented Props: These designs introduce air into the propeller blade’s water flow, reducing drag and allowing the engine to spin up faster, which is particularly useful for acceleration and reducing cavitation.

Materials Used in Propellers

Aluminum: Aluminum propellers are lightweight, less expensive, and offer good performance for general use. They are, however, more susceptible to damage from impact and corrosion, especially in saltwater environments.

Stainless Steel: Stainless steel propellers are more durable, offering better performance and longevity. They are less likely to suffer damage from small debris or impacts, making them ideal for high-performance and offshore applications. Stainless steel propellers are also better at maintaining their shape under high stress, which can improve efficiency.

Effects of Damage on Propeller Blades

Time for a New One

Small dings, dents, or damage to the leading edge of a propeller blade can have a significant impact on performance. Even minor imperfections can disrupt the smooth flow of water over the blade, causing:

Reduced Efficiency: Damaged blades increase drag, reduce the propeller’s thrust, and decrease overall fuel efficiency.

Increased Vibration: Damage can cause imbalances in the propeller, leading to vibrations that affect comfort and can cause additional wear on the engine and drivetrain.

Cavitation: Nicks and dings can create areas of low pressure on the propeller blade, contributing to cavitation, which reduces performance and can further damage the propeller over time.

Causes of Cavitation

Cavitation occurs when the pressure on the propeller blades drops below the vapor pressure of the water, causing bubbles to form. These bubbles collapse violently, which can damage the propeller and reduce its efficiency.

Cavitation can be caused by several factors:

Improper Propeller Selection: A propeller with too high a pitch for the boat and engine can cause cavitation because the engine cannot reach sufficient speed to maintain adequate pressure on the blades.

Sharp Turns: Turning sharply at high speeds can increase the load on the propeller blades and create low-pressure zones, leading to cavitation.

Damaged or Worn Propellers: Nicks, dings, and wear on the propeller can disrupt the water flow, causing cavitation.

High Engine RPMs: Running the engine at very high RPMs can create a situation where the propeller is moving faster than the water flow, causing cavitation.

Selecting a Propeller for Different Operations

Choosing the right propeller involves balancing pitch, diameter, material, and the specific needs of the boat’s operation. Here are some general guidelines:

Cruising: A high-pitch propeller can improve fuel efficiency and cruising speed. Stainless steel propellers are ideal for durability and performance, especially in offshore conditions.

Watersports: A lower-pitch propeller can provide better acceleration and pulling power for activities like waterskiing and wakeboarding. Aluminum propellers are often sufficient for this type of operation.

High-Performance: Racing and high-performance boats benefit from specially designed stainless steel propellers with a focus on maximizing speed and reducing drag. Cupped and vented props are common choices for these applications.

Fishing and Offshore: Durable stainless steel propellers with a moderate pitch provide the best balance of speed, fuel efficiency, and durability for long-distance and offshore fishing boats.

Engine Types and Propeller Pitch

Outboard Engines: Outboards often use a variety of propellers, depending on the application. Lower-pitch props are good for smaller, high-revving outboards, while larger outboards can handle higher-pitch props for better speed and efficiency.

Inboard Engines: Inboard engines typically use larger, higher-pitch props, which are suited for the lower RPMs and higher torque of these engines. Inboards often prioritize smooth operation and fuel efficiency over top-end speed.

Inboard/Outboard Engines (Sterndrive): These engines can use a wide range of propeller types and pitches, depending on the boat’s intended use. They are versatile, allowing for prop selection that matches a variety of performance needs, from watersports to cruising.

Here is a video explaining the pitch vs attainable RPM on your engine.

Propeller Safety

One simple propeller strike can be deadly. A strike to the leg, arm, or even ankle can cause an artery to be cut and the person to bleed out in less than 1 minute – less than the time it takes to get them out of the water.

Here are some good practices to follow to prevent propeller strikes. This applies to small and large vessel operations.

- Wear a Kill Switch Lanyard: On smaller boats in particular, attach the engine’s kill switch lanyard to the operator at all times. This ensures that the engine shuts off if the operator is thrown overboard or loses control.

- Assign a Spotter: When towing swimmers, skiers, or wakeboarders, always have an additional person dedicated to watching the person in the water and alerting the operator to their position.

- Shut Off the Engine When People Are Entering or Exiting the Boat: Ensure that the engine is off when passengers are getting into or out of the boat, especially when swimming or using a swim platform.

- Avoid Reversing Near People in the Water: Be extremely cautious when reversing, as it can increase the risk of a propeller strike. If there are people in the water nearby, avoid reversing the boat entirely.

- Use Propeller Guards: Consider installing a propeller guard or other protective devices designed to minimize the risk of injury from propeller contact.

- Post a “Propeller Warning” Sign: Use clear, visible warnings to remind all passengers and swimmers to stay clear of the propeller area.

- Slow Down in Areas with Swimmers: Reduce speed when operating in crowded or designated swimming areas, and keep a lookout for swimmers who might be difficult to spot.

- Educate Passengers: Make sure all passengers know the risks associated with propellers, especially children and less experienced boaters, so they can act safely around the boat.

Conclusion

Selecting the right propeller for a large powerboat involves understanding the relationship between pitch, material, and design in relation to the boat’s intended use and engine type. Advances in propeller technology continue to improve efficiency, performance, and durability, making it easier to find a propeller that meets specific needs while maximizing the boat’s capabilities. Proper maintenance and regular inspection of the propeller are also crucial to maintaining optimal performance and preventing issues like cavitation and vibration.

Be especially careful and prudent when people are in the water.