Engine Cooling System

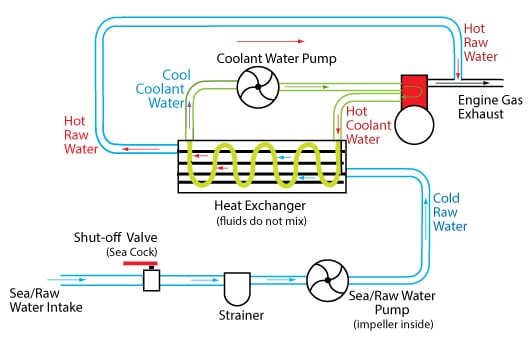

Marine engines on powerboats, whether gasoline or diesel, use two primary cooling systems to manage engine temperatures: the raw water system and the coolant water system. Both systems work together to ensure the engine operates within a safe temperature range, preventing overheating and maintaining optimal performance.

Engine Cooling Water Systems

1. Raw Water System

The raw water system uses water from the body of water in which the boat is operating to cool the engine. This water, known as “raw water,” is drawn from outside the hull and pumped through the engine’s heat exchanger to absorb heat from the engine’s internal coolant.

Components and Operation

- Raw Water Pump: The raw water system is driven by a raw water pump, typically powered by the engine itself. This pump uses a rubber impeller to draw water from outside the boat and circulate it through the heat exchanger.

- Heat Exchanger: In the heat exchanger, the raw water absorbs heat from the coolant water, lowering the temperature of the coolant before the raw water is expelled overboard through the exhaust system.

Maintenance

- Impeller Inspection: The raw water pump’s impeller is a critical component that should be inspected regularly, at least once a year. Over time, the impeller can wear out, crack, or break, especially if it runs dry or encounters debris. A damaged impeller can lead to reduced cooling efficiency or engine overheating.

- Raw Water Strainer: It is also essential to check the raw water strainer, which filters out debris before it enters the cooling system. A clogged strainer can reduce water flow and cooling efficiency. It is often the reason for an overheating engine – accordingly, it should be cleaned regularly.

2. Coolant Water System

The coolant water system, also known as the closed-coolant system, uses a mixture of freshwater and antifreeze (coolant) to cool the engine internally. This system circulates coolant through the engine block and cylinder head, absorbing heat generated during combustion.

Components and Operation

- Coolant Pump: The coolant water system is driven by a coolant pump (circulating pump), which is also typically engine-driven via a belt or gear mechanism. This pump circulates the coolant throughout the engine and into the heat exchanger.

- Heat Exchanger: The heated coolant is then pumped into the heat exchanger, where it transfers its heat to the raw water. The cooled coolant is recirculated back into the engine to continue the cooling process.

- Closed Loop: Unlike the raw water system, the coolant in the closed-coolant system never exits the engine area. It is a closed-loop system designed to continuously recirculate the coolant, preventing corrosion and maintaining consistent engine temperatures.

Maintenance

- Coolant Level and Quality: Regularly check the coolant level in the reservoir and ensure it is topped off with the appropriate mixture of water and antifreeze. The coolant should also be replaced periodically to maintain its effectiveness and prevent corrosion.

- Coolant Pump Inspection: Inspect the coolant pump for signs of wear, leaks, or damage. The drive belt should also be checked for tension and wear, as a loose or damaged belt can reduce the pump’s efficiency and lead to overheating.

- System Flushing: The coolant system should be flushed and refilled according to the manufacturer’s maintenance schedule to remove any buildup of deposits that could reduce cooling efficiency.

Conclusion

Both the raw water and coolant water systems are crucial for maintaining the optimal operating temperature of marine engines. Regular maintenance, including inspecting pumps, checking fluid levels, and replacing worn components, is essential to ensure these systems function effectively and to prevent engine damage due to overheating. Proper care and maintenance of these systems will help extend the life of the engine and improve overall boat performance.